From Sorrow To Substitution To Solution.

I own, use, and really like my Veritas Plow Plane. The only thing that has ever been a bother is the depth stop. I understood this was a known problem before I bought the plane, yet I still bought it. The accepted solution to the problem has been to use a pliers to tighten this knob and those holding the fence steady.

I know there's someone out there who came up with a small fitted strap wrench to tighten the knobs without marring the brass like pliers can, (forgive me if I can't remember the name, I only caught a photo a while back, If someone comments or emails me the info I will add it here as an edit) Personally I think if the strap wrench proves popular it will lead to an increase in problems like this. Without the threat of mangling, those inclined to torque hard will end up twisting off their knobs all the time. (insert adolescent snickering)

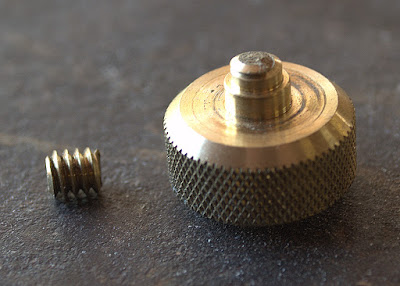

The issue is, no matter how well I torqued the depth stop knob it would inevitably slip. A few weeks ago, my efforts led to the failure of the brass alloy and sorrow in the shop.

I emailed Lee Valley right away. Their customer service is awesome! Even on a Saturday I had an answer back in a little over an hour and a couple replacement parts, including a new depth foot to "experiment" with, on the way. The rep suggested I rough up the post of the depth stop foot with sandpaper to try and give it a better grip but he admitted it's not a great solution but Lee Valley is aware of the problem and working on it.

My issue it the depth stop feels like an afterthought, something slapped on the side, which is out of character with the rest of my Lee Valley experiences. I think one (or all) of three things could improve the design.

1. The post is round and on the small side, something with more beef and shape would seem easier to grip, especially if the post were triangle shaped or square, Give me some surface space to tighten into because a cylinder requires a specific tight tolerance to grab.

2. The teardrop shaped clip that holds the post is a hollowed out casting and only contacts the post at two narrow points, If they were to make this a solid strong piece with contact along the whole face you would increase your odds of a good grip, even if you stayed with the cylinder post.

3. Lastly if everything is to stay as it is, then make the knob out of something more resistant to the torque of a pliers or strap wrench, steel would be nice, something in a grade 8 bolt variety please.

This afternoon I decided to try roughing up my post as suggested. I attacked it fairly aggressively with some heavy grit emery fabric in a circumferential fashion. I also roughed up the contact surfaces on the plane body and the teardrop clip.

Even tightened down with pliers, I can move the depth stop by pushing against it with my thumb. Substitution attempt failure.

My solution was to brandish a fairly new tool to the shop. A Starrett 237 Depth Gauge I picked up last month because a little voice in my head told me I'd need one, though I wasn't sure why. I skipped the depth stop and ran the plow plane until my eyes told me I was close to my target depth of 3/8", then I checked with the depth stop and refined from there.

Not completely as convenient as a well designed depth stop would be, but a passable, and (more importantly) reliable solution.

Ratione et Passionis

Oldwolf

Perhaps the locking mechanism of the Starrett depth gauge holds the key to the upgrade Veritas needs to implement.

ReplyDeleteRegards,

Mike

They have gone for style (or simplicity of production) rather than function. There is not enough surface contact to keep it from slipping Probably the best solution for that without making lot of new parts would be to glue a bit of thin leather on the inside the notch. Like from a worn out wallet. It will crush and make a lot more surface contact.

ReplyDeleteI sawed a slot across the top of the screw with a hacksaw. I tighten it with a screwdriver. Works great.

ReplyDeleteI hate this! I've tried roughing up the post and everything else with sandpaper, doesn't work. My solution: I ordered 6 replacement knobs and keep my broken screw extractor close at hand. Note that I've broken these stupid brass knobs with both a pliers and just using my hand(maybe I'm stronger than I think)

ReplyDeletePerhaps the shank could be threaded and a jam nut put on the shank could ride against the bottom surface of the plane. With the proper thread pitch it would provide a micrometer setting to the depth stop.

ReplyDeleteGoing further the design of the plane could be adapted so that a captured nut could be on the top of the shank. Then the depth could be easily adjusted and the nut wouldn't limit the travel of the depth stop as much. This could be accomplished by creating a block of material that will bolt to the side of the plane, replacing the clamp. The block would have a vertical hole bored through it and a captured nut at the top. The nut can be set into a slot or held with a pin through a horizontal hole in the body of the block. The pin could engage a groove around the barrel of the captured nut.

With the foot of the depth stop riding along the side of the plane and the captured nut holding the vertical position the depth stop would be easy to use and much more durable.

When I was working in a laser lab, we used post holders (hollow anodized aluminum tubes) to hole the optical posts in place. The worst ones had just a 1/4-20 tapped hole on the side. The screw would bite down on the post and chew it to pieces after a while. But the best ones were the "no-slip" variety from Newport:

ReplyDeletehttp://www.newport.com/VPH-Series-No-Slip-Optical-Post-Holders/998772/1033/info.aspx

They have a small rectangular pad inside the cylinder so that when you tighten the screw you are clamping this pad against the post. You can use a stronger screw to get more torque without the danger of snapping the screw. And because of the increased surface area of the pad, you don't risk chewing up the post. Plus, the pad is a slightly softer material that grips the post extremely well.

Newport also makes a cam style that gives you good leverage, but they've got a patent on that one. (Maybe on the no-slip as well).

http://www.newport.com/Cam-Lock-Optical-Post-Holders/999020/1033/info.aspx#tab_Overview

As for improvements, this thread got me thinking again and I just emailed Veritas with this idea(fingers crossed they actually implement it). It seems to me they could just make the post on the depth stop longer, maybe a little thicker, and then use a collet to lock it into place, similar to how the fence is locked into place. The fence on this plane won't budge for anything, so if they applied that same collet setup to the depth stop, I believe this would be the most perfect plow plane ever designed!( at least for it's size, I'm still holding my breathe for the "large" plow plane from them).

ReplyDelete