Posts

Showing posts from December, 2017

Posted by

Derek Olson (Oldwolf)

Work With Your Hands And Think On Your Feet,

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

From Chaos With Love.

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

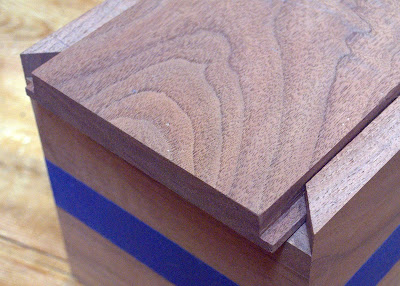

Mitered Corners

- Get link

- X

- Other Apps