Posts

Showing posts from 2015

Posted by

Derek Olson (Oldwolf)

The Studley Effect.

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

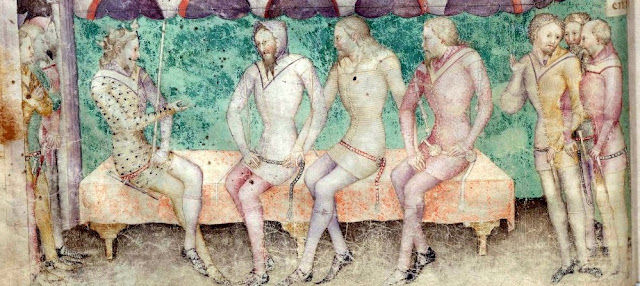

Detail in Medieval Manuscripts

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

Put A Medieval Finish To It

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

The Studley Effect

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

A Tray For Tea Part 4: Finished Up.

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

Gut Instinct

- Get link

- X

- Other Apps

Posted by

Derek Olson (Oldwolf)

Step Stool Morning

- Get link

- X

- Other Apps