Outlier

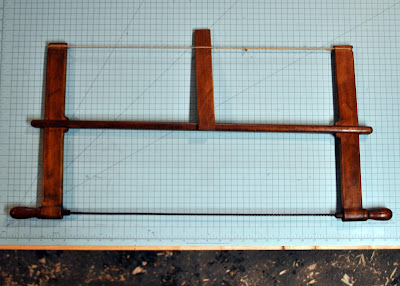

Mrs. Wolf and I were determined to waste a day together in downtown La Crosse. There was a good sushi, a stop in the comic book store, a walk downtown, coffee, and a couple hours inside our favorite antique mall. Of course a few comic books followed me home but the other orphan was this unique turning saw I couldn't pass up.

If you've been reading here more than a second you know I'm enamoured of the old ways of working wood, not for love of the labor but in the belief there was something known that's been nearly forgotten. Turning saws and frame saws are not a new obsession. Making one has been on my "list" for too long. I have the hardware and blades sent to me by a friend, but other things seem to bump it off the top of the list.

Still when lifted this saw from the peg board hook to have a look I wasn't sure at first I was seeing it right.

I've only ever seen these saws with tenons on the ends of the cross arm and mortises in the uprights. This outlier turns that assumption on it's head. And I'll admit the construction in this way seems more straight forward than the more traditional route.

The cross arm falls on a small flat on the upright and is balanced on a moulded "button" (for lack of a better term)

I decided I had to bring it home and give it a test out to see if this was actually a usable form or if it was a ticking time bomb of tension. After replacing the two wraps of supplied bailing twine with some heavy duty linen cording, giving the saw teeth a light brush pass sharpening and tensioning the works up I was very happy to find I had a useable tool in my hands instead of just a tool shaped object.

The tensioning paddle is an obvious later replacement, probably added simultaneously to the bailing twine's arrival, but the rest of the piece carries all the layout lines and subtleties of being made with hand tools. Clearly the maker/owner J. Tonning was proud of the work as he stamped his name on each part on nearly every surface.

I'm more than happy to add this weirdo to my nest of saws and given time may make another just like it. Enjoy the photos.

Ratione et Passionis

Oldwolf

That's a great find Derek!

ReplyDeleteIt's about twice the length of many turning saws (mine has a 12" blade), but still looks quite light. Lightness in a turning saw is one of the things I like most about them. Very heavy for resawing, very light for fine curve sawing.

The interesting construction reduces the usual failure points (curved arms that don't match grain) and make for lightness.

I think you'll really enjoy this one.

Nice saw! I keep meaning to make a better blade for my 12" antique model. I retrofit it to take the Grammercy blades years ago, but I'm not that fond of those blades.

ReplyDeleteI like this style without the mortise in the arms. It's a common setup in continental European bowsaws, although the more modern German saws (Ulmia, ECE, etc.) seem to have gone for the English mortise method. Take a look at Frank Klausz's bow saws to see what I mean. His use a similar design to yours. No "buttons" though. Not sure that piece is entirely necessary for function. Looks prettier with them though.

Here's Frank's saws https://www.popularwoodworking.com/techniques/bowsaw_basics.

Nice looking saw! I have a Swedish bowsaw that is a lot like the one Bob Rozaieski describes above. The main beam is a softwood, perhaps pine, and the end beams are beach, IIRC. It works great.

ReplyDelete